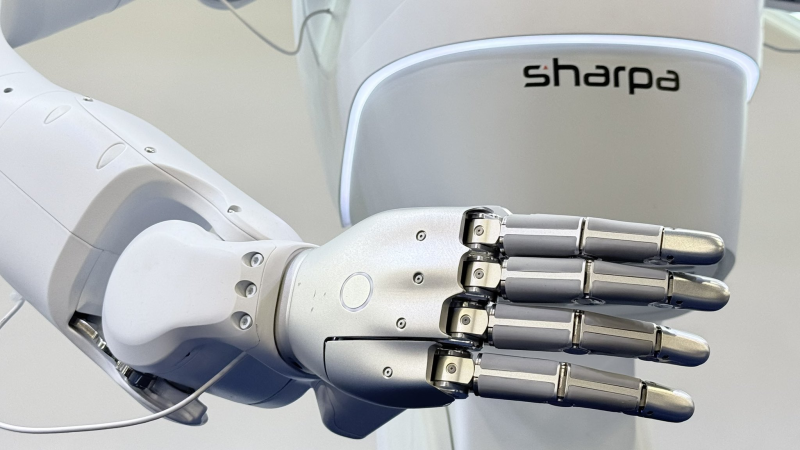

⬤ A striking close-up image from CES reveals Sharpa's cutting-edge humanoid robotic hand, packed with articulated fingers, miniature actuators, and dense sensor networks. The design became a talking point at the trade show as engineers debated whether this represents the next evolution in humanoid robotics. Mounted on a robotic arm, the hand emphasizes surgical precision over flashy packaging—this is engineering at its finest, not a finished product ready for store shelves.

⬤ What makes this hand remarkable is its sensory depth: roughly 1,000 sensors crammed into each finger, bringing it tantalizingly close to human touch sensitivity. Demonstrations included playing ping pong, dealing cards, precise paper folding, and intricate origami—tasks demanding split-second feedback, delicate force calibration, and pinpoint accuracy. These aren't party tricks; they're proof that robots can finally handle fragile, flexible materials without crushing or dropping them.

⬤ Conversations at the event also touched on semiconductor developers working to embed dedicated AI chips right inside robotic hands. This local processing setup would let the hand "think" on its own, cutting down lag time and making split-second adjustments during complex manipulation. It's part of a bigger shift toward edge intelligence, where brains live closer to the hands instead of waiting for orders from a distant computer.

⬤ While nobody officially confirmed this hand will end up on Tesla's Optimus robot, it's clearly being watched as a potential blueprint. The takeaway from industry chatter is simple: breakthrough dexterity at the hand level unlocks everything else. Without it, humanoid robots stay stuck doing simple lifting and walking—with it, they can start tackling real-world jobs that actually require a human touch.

Eseandre Mordi

Eseandre Mordi

Eseandre Mordi

Eseandre Mordi